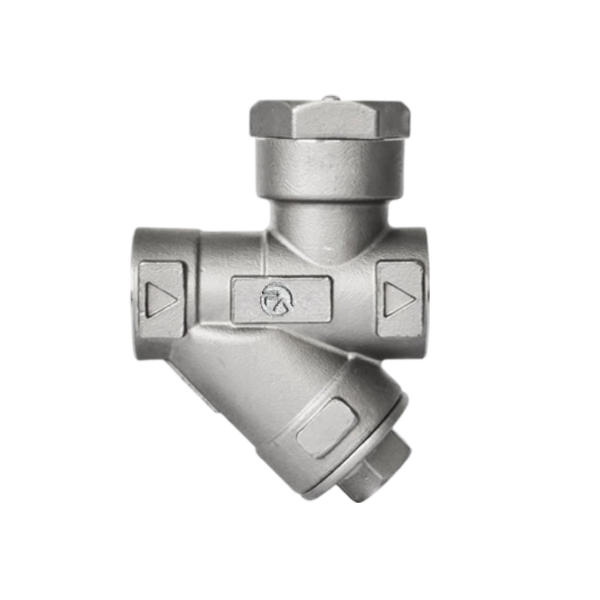

Steam Trap Manufacturer

Steam Trap Technical Information

SCREW END : ANSI B 1.20.1

SOCKET WELD END : ANSI B 16.11

A steam trap is a mechanical device used in steam systems to efficiently remove condensate (water formed from condensed steam) and non-condensable gases while preventing steam from escaping. This is essential for maintaining the efficiency and effectiveness of steam heating systems, such as those used in industrial processes, heating, and power generation.

Key Functions:

- Condensate Removal: Discharges condensate to keep steam lines clear and operational.

- Gas Removal: Eliminates air and other non-condensable gases that can reduce system efficiency.

- Steam Retention: Ensures that steam remains in the system for heating and other applications.

Types of Steam Traps:

- Mechanical Traps: Use physical components like floats or buckets to open and close the discharge.

- Thermostatic Traps: Operate based on temperature differences.

- Thermodynamic Traps: Use pressure differentials to function.

Importance:

- Efficiency: Enhances heat transfer and overall system performance.

- Safety: Prevents issues like water hammer and system overpressure.

- Cost Savings: Reduces energy waste and operational costs.

Download Drawing

Download Drawing